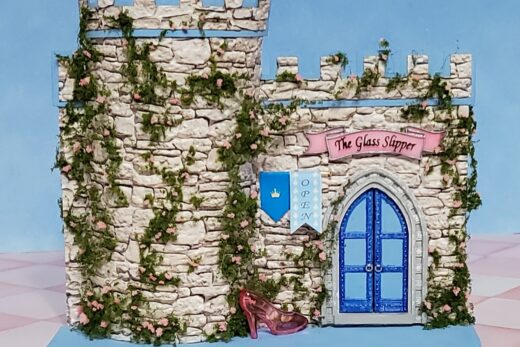

For Camp Make-a-Mini 2022 on create.miniatures.org we have a NAME Logo House as our project. I did a Lunch n Learn on adding lights to the house, to view click here.

To get ready for the demo on lighting, I needed to put the interior together. I’ve already assembled the exterior box – see my prior post here.

Apply wallpaper

Before putting the interior box together, it is a good idea to add the wallpaper. The box has groves already for the lighting on either side. I’m going to be using the right side only because my wires are really thin.

When applying the wallpaper, I will be extending the paper over these grooves on either side. I used spray adhesive for the wallpaper the same used for the exterior. When placing the paper, I used the groove for the floor as my guide. On only one paper did I need to trim the top. I just want the floor pieces to fit without any extra from the wallpaper.

I also pay attention to the sides were there are notches. The paper should not extend beyond or onto the notches.

I continue adding the wallpaper to the the three walls making sure everything lines up. I also paper both ceiling and floor for the attic. However I don’t add ceilings paper to either of the in between floors.

Assembly of part of interior box

Before gluing the interior box together, I recommend that you test whether it will fit easily into the Exterior box.

Then I assembled all pieces except three: the right side wall, two floor/ceilings.

Maybe this picture collage will help.

A. This is the building of the interior box with out the right side wall.

B. What the interior box looks like from the front without side wall. Now that even the base (basement) is enclosed. I had a bit of trouble gluing this so I glued it separately and clamped to hold in place properly.

C. I am showing that the floor papers are installed.

D. The ceiling papers are not installed yet.

Windows

In my Exterior box post, I discussed my decision to only use the paper windows on the inside. I trimmed them neatly so I got the red frames.

To apply them, I want them to align across the sides and back and then from floor to floor. To help, I cut a spacer from scrap cardboard. It is 3/4 inch tall for the first floor. Width is not important.

To align from first to second floor, I used a square window as a spacer between wall and window I was gluing. I could have cut my cardboard in a L shape instead. I would flip for the other side.

The second floor is not as tall as the first one so I cut a second spacer. This one was 1/2 inch high. I also realized I could use the first floor spacer to the side between the walls and the windows. I glued the two together.

Lighting

I did a video demo of how I have added lights to this house. However here is a step by step.

Dia had already cut grooves for wires which made this way easier. However she did not for the attic. I didn’t light my attic, but were I to do so I would have the wires hanging from the ceiling /rafters. If grooves were desired, then I’d use my Stylo + tool or a utility knife.

I chose to use 2 warm white 3v chip LEDs. I glued the light in the middle of the circle and the wire in the groove going out to the right side. The glue I used was tacky glue with drops of super glue gel. It was held in place for drying by the blue tape.

I did not drill any holes for the lights because my lights were placed on the ceiling side. My floor paper went on the smooth side. A template was provided to know where to add a hole in the ceiling paper. I used a craft knife since my hole punch didn’t reach.

Once the lights were glued in, I realized I really needed longer wires for the light for the second floor to reach the battery. Not to worry, I will add some wires to make them longer. Obviously it would have been easier to order them that way, however when I was ordering, I couldn’t find the longer ones. (I should have asked.)

Adding length to wires

When a wire wasn’t long enough to reach the battery, I added what I call a leader wire.

Electrical Plan

It’s always good to make an electrical plan. It doesn’t need to be as fancy as this just a simple line drawing works. Most often I don’t need one but for understanding the leader wires and connecting two lights, I’ve included one here. The more complex the plan the more likely I will create one.

In my drawing the leader wires connect side by side. As long as the connections (any place with bare wires) are covered then they can be side by side. I prefer using shrink tubes.

With the Logo House, I needed to offset the connections because they would not fit in the groove down the side. Plus there was a tab that made the groove tighter.

I decided to undo both sides because where the connection was would be right at the tab. I cut the LED wires offset this time so they would hopefully land near the second floor groove above the tab. I reconnected to the leader wires.

Connection to Battery and Switch

I purchased a 3v coin battery holder with switch. I could have combined myself but it is nice to have this together. I choose coin battery because I prefer those but after full assembly, I think it is needed for the quarter inch scale version. The opening for pulling out the battery holder to change it is tight for anything else.

To combine my two lights and the wire to the switch, I twist the three wires together and then solder. Since I choose to have the three wires together this way I didn’t have to worry about the shrink tube. However if I have soldered them in a line in a Y formation soldering the two to the one at the stick, then the shrink tube must be on my wire before I solder.

Adding wiring to house

Since there were grooves already cut, it was just gluing every thing in place. I already glued the lights in place. I applied the ceiling paper over the wires being careful to not press in the groove. Next I glued in the floors to the left and back.

Next iI glue the 2nd floor light wires in the side groove using tacky glue and super glue gel.

I move to the 1st floor wires and tuck those in first behind the tab. Then I tucked the ground wire for the 2nd floor in place. It has the connection before (or above) the tab. The hot for 2nd floor has not been tucked in yet.

Glue applied along the 1st floor. Then everything is tucked in the basement.

I was concerned that just super glue gel would not be strong enough to keep the switch in place. I added scraps of wood to go around. I glued those on with wood glue. Then glued the swatch with super glue gel.

The right side is now glued in place. I used bar clamps to hold in place overnight.

Spray paint the outside of the interior box

I used wax paper to block the spray just in case. Dia suggested pressing against the box to create a pattern. Good idea. I used the pattern to trim away the edges. Mine is slightly smaller. I used blue tape then to hold against the edges. I am keeping the natural mdf color for the edges.

The blue tape was trimmed so none was folded on the sides.

I did two coats of the red spray paint on three sides and the back. The left side will be covered next.

Notice the switch is easy to access.

Add exterior pull panel to interior box

Prep: I determined that the best way to apply in the correct place was to have the interior inside the exterior box. This is because my exterior box is completely finished. I tried to draw around the interior box but it was difficult to stay positioned. Instead having them together worked out great. I am just cautious to not have excess glue.

Before using the epoxy I roughed up both surfaces to be glued together with gritty sandpaper. I also put blue tape on my clamp heads just in case. Then I went outside.

I had purchased the epoxy glue as recommended. I have not used two part epoxy for many years. I was trying to be careful but I didn’t wear gloves. In the process of getting the plunger to expel air, I squirted some on the back of my hand. I didn’t have any rags outside with me so I had go get one and wash my hands. Thankfully it did not cause any harm.

I mixed and applied the epoxy. I placed the pieces together and then clamped. The clamp heads were right on top of the window frames I had applied to the outside, hence my concern of scratching them with the heads. I left the clamps on overnight.

The interior is officially finished until I go about furnishing it.

I only painted green at the top because it shows when closed.

The wallpaper in the right corner is a bit worn in spots due to adding the wiring in the groove. I did this several times due to my doing the lighting demo. However not to worry as I will cover it whenever I furnish. I do now understand why Dia used flaps at her corners. I would instead recommend applying the side wallpaper over those flaps once the back is wallpapered. Another option is to use much smaller flaps less than 1/4″ wide.

Comments always welcome.

Happy Miniaturing!

Tiny Hare aka Preble